How To Install A 9x7 Garage Door

Earlier getting started on the replacement, it is essential that nosotros begin these instructions with our sternest warning:

CAUTION! Replacing garage door torsion springs is dangerous because the springs are under tension. If you lot practice not use the right tools and follow condom procedures, y'all could lose hands, limbs, or even your life. You could likewise impairment property. Nosotros want your business, only non at the expense of your well beingness. Doing the chore correct is your responsibility. If you have any doubts nigh your ability to change your springs safely, nosotros recommend you hire a professional to repair your garage door. Safety Beginning! Then piece of work.

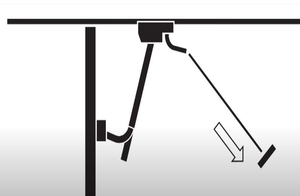

one. To brainstorm, if an opener is installed, disconnect the opener drawbar arm from the garage door. You will typically need to remove a clevis pivot past first taking off the cotter pin, every bit pictured.

2. Unplug the power to the opener. This will proceed the opener from running if somebody accidentally tries to open the door while you lot are working.

3. Vise grip the vertical track about 3" above ane of the rollers. If you install the wrong springs, or if you lot over-wind the leap, this volition foreclose the garage door from flight upward and knocking you off your ladder after winding the jump. This has happened to me on more than one occasion.

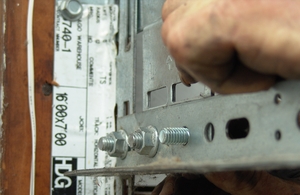

4. After installing the horizontal tracks on a new door, or after removing the existing bound assembly, install the the end begetting plates. This must be on the within of the horizontal angle and vertical flag subclass. The narrower outer race of the bearing should face up toward the outside of the garage door.

5. Insert 2 carriage bolts and finger-tighten the nuts to secure the end bearing plate to the track angle as before.

6. Secure the top of the end begetting plate to the jamb with a lag screw equally earlier.

vii. Tighten the nuts to secure the bottom of the plate to the horizontal bending.

eight. Insert the left end of the 1" outside bore shaft into the end bearing plate.

nine. Go to the right side and slide the new end bearing plate onto the shaft. Make certain the cease bearing plate is installed on the within of the flag bracket and horizontal track angle. The inner protruding race of the begetting faces the inside of the garage as pictured. The new cable drums will press against these inner races of the bearings.

10. Install at least 2 bolts on the bottom the cease bearing plate to secure it to the horizontal track bending. On 12" radius tracks such as this the third bolt securing the end begetting plate to the flag bracket is optional if the top of the subclass is to exist secured to the jamb. On 15" radius tracks the horizontal runway angle connects to the meridian of the flag bracket and is not supported by the flag subclass. Finger-tighten the flange nuts to find the best placement of the stop begetting plate.

xi. Secure the top of the end begetting plate to the jamb with a 1 three/4" X v/sixteen" lag screw. Important! Failure to exercise this on xv" radius tracks often causes the subclass to lean out, cutting the shaft, wearing out the bearing, and frequently causing the cables to come up off the drums. Caution: Do not break whatsoever of the wires when you secure the end bearing plate. The wire for the motion sensor eyes typically runs well-nigh the terminate bearing plate. Make sure the wire is not under the metal.

12. Tighten the nuts that secure the end bearing plate to the horizontal angle and vertical flag bracket.

thirteen. Mensurate the distance from the tiptop of the garage door to the middle of the shaft. Tape this dimension.

14. Measure this distance from the top of the door to the header. Make a line at this altitude with a pencil or a marker.

15. Hold the spring anchor bracket against the header as shown. The line you made in the previous pace must line upwards with the notch in the bracket. The longer end of the spring anchor subclass needs to be on peak.

sixteen. Predrill the top of both adjustable slots in the spring anchor bracket. Additionally, predrill the stationary hole in the bottom of the bracket.

17. Secure the spring anchor bracket to the garage door header where y'all pre-drilled using lag screws. Notice that I moved the spring ballast bracket a piffling to the left. Since the bolt on the correct side of the garage door header was in the fashion of the subclass, I had to motility the bracket. Though information technology is not quite centered, this will not bear upon the performance of the garage door. If you practise this, brand sure you secure the bracket in the center of a board on the header.

eighteen. Vise grip the leap anchor bracket equally shown. This will go along the shaft from possibly falling out and causing injury or dissentious the garage door or shaft.

xix. Move to the left side of the garage door. Slide the shaft out of the end bearing plate and slide a bearing on the shaft as shown. Note: the bearing should face the same direction as the end bearing plate on the left.

twenty. Slide the jump that you placed on the left side of the door at the beginning onto the shaft as shown. The stationary cone must exist toward the center of the garage door while the winding cone must be toward the exterior of the door.

21. You lot may need to loosen the set screws for the spring to slide onto the shaft.

22. Slide the jump and bearing toward the center of the door.

23. Loosen the prepare screws on the cable pulsate.

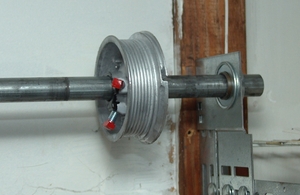

24. Slide the cablevision pulsate on the shaft as pictured.

25. Insert the shaft back into the end bearing plate.

26. Motility to the right side of the garage door and repeat this process. Start by pulling the shaft out of the end bearing plate.

27. Slide the cable drum on the shaft as shown. Insert the shaft back into the end bearing plate.

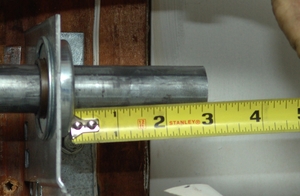

28. Measure to see how far the shaft extends across the end bearing plate on each side of the garage door. Center the shaft by equalizing this distance.

29. Remove the vise grip from the spring anchor bracket. Slide the bearing toward the bracket and lube the bearing and the shaft with 2-iii drops of oil.

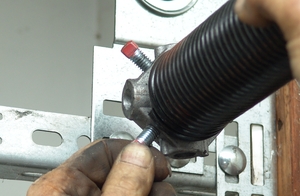

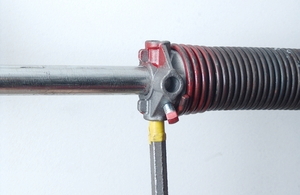

30. Insert the bolts in the stationary cones of the new torsion spring, and insert the bolts in the slots on the leap ballast bracket. Make sure that the bearing is inside the stationary cone. Finger tighten nuts on bolts until the stationary cone is flush against the center bearing plate.

31. Forcing the cones by tightening the bolts may break a cone if information technology is communicable on a begetting. Winding garage door springs with croaky cones can cause the springs to spin loose and the confined to fly. Secure the bolts.

32. If you are converting from a Torquemaster or an extension spring arrangement, remove the old cable from the lesser fixture. You may need to apply a screwdriver to get the cable off.

33. Install the new cable. If this is a new installation, you may accept installed the cables before.

34. Slide the cable drum toward the end bearing plate until the cable pulsate is flush against the race of the bearing. Finger-tighten the set up screws on the cablevision drum.

35. Tighten each prepare screw an boosted 1/2 to three/4 plough. Circumspection: Nether-tightening the drums could cause the pulsate to slip and the door to cock or fall. Over-tightening the set screws could impairment the shaft or drum, resulting in the same problems. This is a critical step.

36. A mutual problem for do-it-yourselfers and inexperienced garage door repairmen is getting the cease of the cable to properly seat in the slot of the cablevision drum. I unremarkably bend the end of the cable 90 degrees with my needle nose pliers as shown.

37. Bending the cable will help y'all avert bug with the tip at the end of the cable catching on the terminate bearing plate and causing the cable to come off and the garage door to jam, cock, or fall. Check to make certain the cablevision is direct in the slot and not sticking out the side. As well the border of the cable stop should non exist pointing to the side as shown. The cable tip should fit completely inside the pulsate, with the rounded part facing out so the tip can't scrape the end begetting plate.

38. Later on inserting the cablevision, pull down on the drum to tighten the cablevision around the outer groove on the drum.

39. Twist the shaft to proceed the cable tightly on the drum. While twisting, vise grip the shaft every bit shown to go on the cable on the drum. The pinnacle of the vice grip should be tight against the garage header. This volition proceed the cablevision snug on the first drum while you install the cable on the other drum and position it in place. It also keeps the shaft from turning and the cables peeling off when you current of air the springs. That unmarried grip tin salvage many hours of walking back and along and having to level and re-level the door after the springs are wound.

40. Move to the left side of the garage door. Insert the cable on the drum. Pull down on the cablevision drum to tighten the cablevision on the pulsate. While pulling downwards on the drum push button the shaft to the correct to make sure the right cable drum is butted snugly against the inner race of the right end bearing. Push the left pulsate against the race of the left finish bearing.

41. While continuing to pull down on the pulsate, finger-tighten the set screws and follow with 1/2 to 3/4 boosted turns with a wrench. Properly following these two steps volition result in both cables having the same tension. After the springs are wound, the garage door will level properly and it will non have a gap nether one end.

42. It is now time to wind the spring. Mark the shaft simply beyond the winding cone to clinch that y'all have installed the correct bound on the correct side of the leap anchor bracket. Torsion springs always grow in length when they are wound in the proper direction. If your bound does non grow as you wind information technology, you are winding it the wrong direction probably because information technology is improperly installed. If this happens, you have the incorrect wind leap and you need to install it on the other side of the middle support subclass.

43. Tape your winding bars, not only to assure that you are inserting the confined completely into the cones as you wind the springs, but more importantly to assure that the bar does not slip out of the cone when yous stretch the leap at the stop. This has happened to me several times. We stretch the springs after winding them considering the shaft floats horizontally between the flexible end begetting plates every bit the door operates. Although this may be a little as 1/4" the binding of the coils every bit the door closes ofttimes keeps the door from closing completely, particularly when the springs and bearings are dry out.

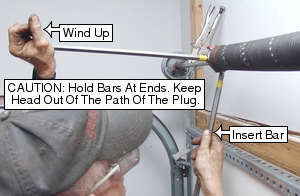

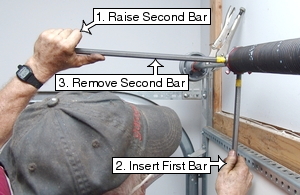

44. At this bespeak you lot will air current the springs. Many garage door servicemen marker the springs with chalk or paint, but you lot can probably air current the springs in the time information technology would accept me to explicate how to read the marks. You volition be winding up on the torsion leap. Begin by turning the spring upward 1/4 plow until it meets resistance. This is your beginning quarter plough. Count "one." Next, insert the bar and enhance information technology 90 degrees. Insert the second bar. This is "two." As you current of air the bound it should grow in length the thickness of one coil for every turn.

45. Heighten the second bar 90 degrees and insert the first bar. This is "three." Continue winding. If the spring shortens in length, unwind the spring and switch sides - the spring is on the wrong side. Otherwise, proceed winding until you reach a count of "xxx." This is vii one/ii turns, which is normal for most 7' garage doors. Newer steel doors with only one strut on top often demand only 7 ane/4 turns. On 8' doors count to 34. Each time you insert a bar into the winding cone, listen for the click to let yous know the bar is in all the fashion. Not inserting the bar all the way could crusade the plug to explode.

46. If the spring comes loose from the plug at near 6 turns, you lot are probably winding the jump backward because you have the wrong wind spring. Put the jump on the other side of the bound anchor subclass. Otherwise, afterwards winding the springs, you volition need to stretch the springs and secure the winding plug. This tin be very difficult, and information technology tin be especially dangerous. On several occasions I have had the winding bar sideslip out of the plug while tightening the set screws. Having the bar marked with tape adjacent to the plug can help to prevent this from happening to you.

47. Mark the shaft 1/4" across the winding plug with permanent marker or with a file. Nosotros stretch the springs because the shaft floats horizontally between the flexible terminate bearing plates every bit the garage door operates. Although this may exist every bit footling as 1/4" the binding of the coils as the door closes often keeps the door from endmost completely, especially when the springs and bearings are dry and demand lubrication.

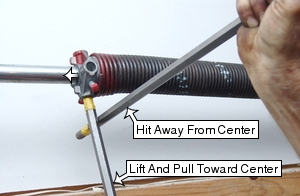

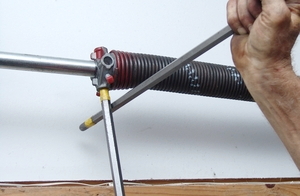

48. Here you volition need to do iii things at once. With your left hand, lift the bar only off the top of the door and pull information technology toward the center of the garage door. While lifting up and back, tap the pinnacle of the bar just under the winding plug with your other bar. Pulling the bar back toward the centre of the door as yous tap causes the bound plug to demark on the shaft and non slip back.

49. Continue tapping until the plug moves out to the mark on the shaft. Go along property the bar off the door and pulling back toward the center of the door. If the plug slips away from the mark, repeat this step. Keep an middle on the tape to brand sure the bar doesn't slip out of the cone. If it does start to slip, balance the bar confronting the top of the garage door, insert a bar in the next hole and turn the plug upwards plenty to allow you to push the marked bar back into identify.

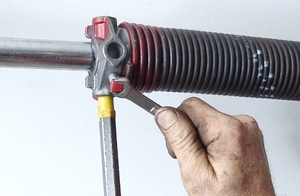

fifty. After the plug reaches the marking, continue pulling the bar off the door and back toward the middle of the door with your left hand. Tighten both set screws 1/2 to 3/4 turns each subsequently each screw first meets the shaft. This is the betoken at which you will feel the screw meeting resistance.

51. Carefully test the set screws by pulling downward on the bar. The winding plug should be tight enough so that when you pull down on the bar, the garage door should begin to lift. If the bar starts to skid when you pull information technology down, add 1/4 turn to each set screw. CAUTION: Before removing the bars from the plugs afterward securing the winding plug, you will need to run an important exam of the door. Many of the accidents that occur while fixing garage door springs are due to installing springs that are too potent.

52. Slowly pull downwardly on the winding bar until the garage door rises 3" and the roller hits the vise grip on the runway. The door will usually drop dorsum down and raise the bar. If it doesn't drop back downwards, elevator the end of the bar until the door closes. If the door comes upwards by itself when you hold the bar lightly, the springs are either over wound or they are too strong. Y'all may need to remove 1/iv to 1/ii turns from the springs.

53. If the door stays on the floor, remove the bar from the cone.

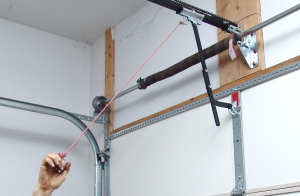

54. If the door stays on the floor past itself, remove the vise grip from the track. If the door is off the floor and the roller is against the vise grip, close the door with one mitt and remove the vise grip with the other. If the springs are too stiff, you have to restrain information technology from flying into the open position.

55. Remove the vise grip from the shaft.

56. Heighten the garage door slowly. Check the door rest. The door should stay downwardly when closed, halfway when opened halfway, and open when opened. Add 1/iv plow of tension to the spring if the door will drop to the flooring by itself from the halfway point. If the garage door won't stay on the floor, and if it pulls itself up when stopped halfway, shut the door and remove 1/4 plough of tension from the bound.

57. Oil the spring. The thicker the oil the longer it volition last. I usually utilise 40 wt. motor oil, only 10W40 volition do if that is all y'all have. Squirt a stream of motor oil across the tops of the springs and rub the oil into the coils. Do not oil the last inch of each end.

58. Bank check the garage door at the floor. It should seal all the style beyond. If it doesn't you may need to suit the drum on the college side to get the door to level.

59. Reengage the garage door opener.

sixty. Plug in the ability cord for the opener. Adjust forcefulness and travel equally needed.

Source: https://ddmgaragedoors.com/diy-instructions/how-to-install-a-single-torsion-spring-assembly.php

Posted by: butlermiltured.blogspot.com

0 Response to "How To Install A 9x7 Garage Door"

Post a Comment